Technical Situation

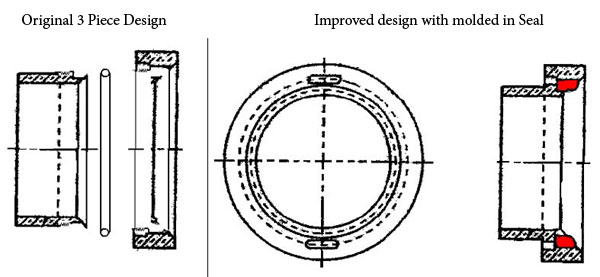

Our customer produced a valve component requiring 2 machined bronze castings and a very complicated assembly to fit an O-ring seal between the 2 components. The customer experienced process difficulty and rework costs to produce a consistent tight seal. They also had a premature wear problem with the rubber O-ring seal.

On a plant visit with the engineer, we became aware of their problem and made suggestions for a quality improvement with the additional benefit of a cost reduction.

Solution

We proposed combining the 2 bronze castings into one part and molding a bonded polyurethane seal ring on the valve component. With the higher strength and wear resistance of the polyurethane the customer achieved longer product life. The customer saved money by eliminating one part and the machining and labor required to assemble the parts. Finally, our process control improved quality and reduced the need for inspection and part rework.